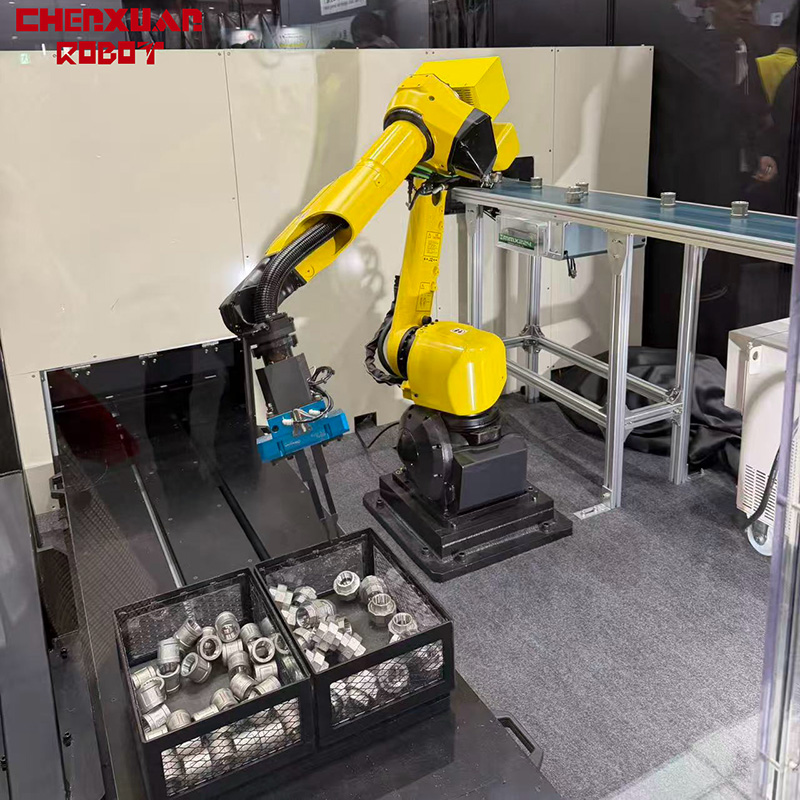

Collision-free Path Planning: AI Automatically Generates Picking and Placing Paths, Avoiding Collision Risks with Material Bins

Product Introduction

1. FANUC's six-axis handling robots are widely used in various handling, assembly, and automation scenarios, especially in situations that require high precision and high flexibility. Six-axis robots offer excellent motion flexibility and can carry out diverse tasks in complex working environments, such as material handling, assembly, packaging, sorting, stacking, and more.

1.1 Parts and Components

Small parts: such as automotive parts, electronic components (e.g., circuit boards, chips), mobile phone parts, and household appliance components.

Mechanical components: such as motors, gears, bearings, pump bodies, and hydraulic components.

Automotive parts: such as car doors, windows, dashboards, engine parts, and wheel hubs.

Precision equipment: such as precision instruments, sensors, and medical devices.

1.2 Precision Devices

Optical components: such as lenses, displays, optical fibers, and other fragile, high-precision products.

Electronic components: such as ICs, sensors, connectors, batteries, and other precision electronic parts, requiring the robot to have high handling accuracy and repeatable positioning ability.

Application Areas

Automotive industry: handling automotive parts, car bodies, doors, and interior components, usually requiring robots with high payload capacity and precise positioning.

Electronics industry: handling circuit boards, displays, electronic components, etc., requiring high precision and delicate operation of small items.

Logistics and warehousing: used for automated warehouse tasks such as handling, sorting, and stacking, optimizing storage and distribution of goods.

Food and pharmaceutical industry: performs excellently in food packaging, sorting, and handling pharmaceutical products.

CORE FEATURES

video:

Our robot

packaging and transportation

exhibition

certificate

Company History